MicroScale Sealed Vessel (MSSV)

Closed System Pyrolysis

An analytical technique developed and shown by B. Horsfield (1989) that employs 40 microliter glass tubes. One end is pre-sealed, while the other end is used to load sample material and then sealed. The tubes are then heated under either isothermal or nonisothermal closed-system conditions resulting in cracking of the sample material. The heated tube is the broken directly in a gas chromatographic inlet for optimum detection of gaseous and liquid hydrocarbons. Various detectors may be employed such as FID, MS, MSMS, and others.

This technique is used in organic geochemistry to evaluate the products formed at various levels of thermal maturity. Kinetics data may also be computed from results at various time/temperature experiments. Analytical work may utilize whole rock, kerogen, asphalenes, resins, soils, polymers and other pyrolyzable materials.

Features

-

Quantitative analytical technique with IS

-

Isothermal and nonisothermal experiments

-

High precision temperature control

-

Programmable flow control using HP GC

-

Cryogenic trapping system

-

Dedicated installation and support system

Applications

Published applications include the compositional kinetic models, phase prediction and polar

compound geochemistry within geological contexts, monitoring of air pollutants, bound biomarker analysis, stable gas isotope determinations and fluid inclusion analysis.

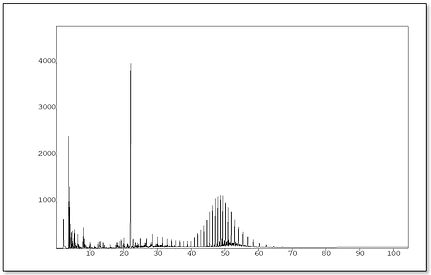

MSSV fingerprint of products formed from Green River Shale; note presence of b-carotane; no alkenes

MSSV yields of various source rocks

High molecular weight waxes (C40+) generated from MSSV pyrolysis of low maturity source rock, Gulf of Mexico, USA

.png)